Stress Relieving

As the name implies, the purpose of this process is to remove internal residual stresses from steels. The stresses may have come from the steel making mills, machining, forming, welding etc. If residual stresses are not removed prior to hardening, distortion may occur, whilst if stresses are left in components before they go into service, then premature failures can result, as well as more subtle movement causing the parts to go out of tolerance.

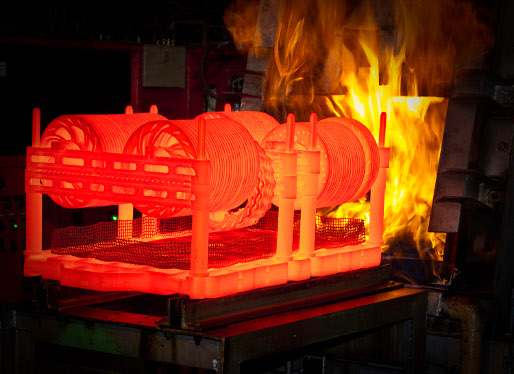

To Stress relieve steels, heat the parts to a temperature of about 650ºC for a minimum of one hour or till the whole part reaches the temperature. This will remove most of the internal stresses. After removing from the furnace, they are air cooled in still air.

Typical parts that benefit from stress relieving are large and complex welded assemblies, castings with a lot of machining, parts with tight dimensional tolerances and machined parts that have had a lot of stock removal or rapid stock removal.